Training about excellence should exhibit excellence. We don't believe in online training. All of our courses are in-person and led by a practicing expert on the topic; not just a theorist. An MBB Consulting™ expert will provide real life examples describing how they've actually used the technique(s). Classes are also fun. Students learn better in a fun and comfortable setting. Case studies and exercises keep our classes interesting and make them much better than boring monologues done by some of our competitors. Many improvement techniques rely on Statistics. And many people find statistics boring. We've found ways to make it fun.

5S Training

5S training shows Lean Manufacturing's 5 steps to organize workplaces in ways that lower cost and prepare students for more advanced techniques.

Read More8 Disciplines of Problem Solving (8D) Training

8D training teaches students Ford's comprehensive 8 Disciplines of problem solving methodology notable for its formal team recognition step..

Read MoreBasic Microsoft Excel Training

Basic Microsoft Excel Training quickly getting students proficient with Excel's most common and useful spreadsheet functions, and techniques.

Read MoreChemical Safety Training

Chemical safety training protects students, their peers, families, and friends from exposure to hazardous chemicals at work and at home.

Read MoreConfined Space Training

Confined space training protects students, their peers, families, and friends from injury in small, occupiable, restricted-egress spaces.

Read MoreDesign for Assembly (DFA) Training

DFA training describes Design for Assembly - how students can minimize total cost through ease of manufacturing and assembling their designs.

Read MoreDesign of Experiments (DOE) Training

DOE training explains Design of Experiments - the strongest root cause analysis technique ranking a problem's causes & fastest way to optimize.

Read MoreFailure Mode and Effects Analysis (FMEA) Training

FMEA training describes Failure Mode and Effects Analysis so students can lessen risk while designing any new system, product, or process.

Read MoreGage R&R Training

Gage R&R training is the standard Six Sigma Black Belt measurement system analysis tool assuring students' decisions are made from valid data.

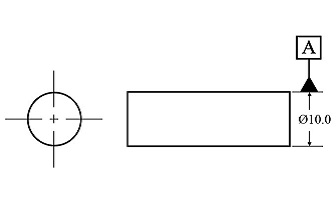

Read MoreGeometric Dimensioning & Tolerancing - ASME Y14.5 2018 Intro. (GD&T1) Training

GD&T training describes Geometric Dimensioning and Tolerancing letting students specify part geometries consistent with their manufacturability.

Read MoreHuman Error Prevention Training

Students improve their knowledge of the psychology and physiology contributing to human error.

Read MoreIATF 16949:2016 Internal Auditor Training

Our Exemplar Global compliant IATF 16949:2016 Internal Auditor Training is a fun, interactive experience led by a SSMBB w/ Big 3 OEM experience.

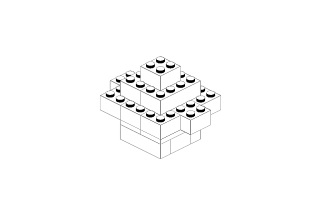

Read MoreLean Lego Game Training

Rather than death by PowerPoint, experience waste, push vs. pull processes, kanban, kaizen, systems thinking, and work cells in a fun exercise.

Read MoreLock Out Tag Out (LOTO) Training

Lock Out Tag Out training helps students avoid injury by zeroing out or controlling energy sources before entering a machine's work envelope.

Read MoreMachine Condition Signature Analysis Training

MCSA training describes Machine Condition Signature Analysis - saving students money by replacing unplanned failure with preventive maintenance.

Read MoreMeasurement System Analysis (MSA) Training

MSA training describes Measurement System Analysis - quantifying measurement error help students avoid making wrong decisions from bad data.

Read MoreParameter Design Training

In an interactive and fun setting. learn how to calculate highest revenue-generating product dimensions.

Read MorePowered Industrial Truck Training

Get forklift certified today in the best training you will ever have.

Read MoreProcess Capability Training

Process Capability Training lets students study and predict processes long-term defect rates and assess their ability to satisfy your customers.

Read MoreQuality Function Deployment (QFD) Training

QFD training describes Quality Function Deployment - product design 'gone right' transforming customer needs into profit maximized launch plans.

Read MoreSingle Minute Exchange of Dies (SMED) / Quick Change-Over Training

SMED training describes Single Minute Exchange of Dies - how students can increase profit by decreasing process changeover-related downtime.

Read MoreSix Sigma Black Belt Training

Six Sigma Black Belt training gives students a full arsenal of world-best improvement powers enhanced with statistical software like Minitab.

Read MoreSix Sigma Green Belt Training

Six Sigma Green Belt training conveys a simple, effective improvement system. Designed for all students, techniques require no advanced math.

Read MoreSix Sigma White Belt Training

Six Sigma White Belt training introduces students and begins their journey toward world-class business excellence concepts and terminology.

Read MoreStatistical Process Control (SPC) Training

SPC training gives students the power to remotely detect supplier process changes.

Read MoreSupervisor 101 - New Supervisor Training

Get a crash course in the critical things every new supervisor needs to know.

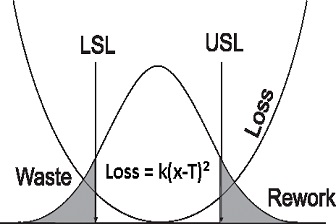

Read MoreTolerance Design Training

In an interactive and fun setting. learn how to calculate the intersection point between internal manufacturing cost and external warranty cost.

Read MoreValue Stream Mapping (VSM) Training

Value Stream Mapping training enables students to visually summarize processes highlighting their waste, and opportunities for improvement.

Read More

1 day

$349 / student

Photo Credit: US Mint