Cities Recommended in Sonora

All Cities

About Geometric Dimensioning & Tolerancing - ASME Y14.5 2018 Intro. (GD&T1) Training

Who is Geometric Dimensioning & Tolerancing - ASME Y14.5 2018 Intro. (GD&T1) Training for?

Anybody who makes or uses engineering drawings should know GD&T. This includes, drafters, designers, engineers of all disciplines, buyers, machinists, maintenance technicians, salespeople, auditors, inspectors, and their management. In our course, Sonora students learn:

Geometric Dimensioning & Tolerancing - ASME Y14.5 2018 Intro. (GD&T1) Training Course Overview:

Prints serve their internal customer users including Product Design, Purchasing, Manufacturing Engineering, and Production. It is important that information be communicated clearly and in a useful manner to these important stakeholders. As such, geometric dimensioning and tolerancing (GD&T) symbology is articulated in ASME Y14.5 to satisfy this need.

Our 2-day introduction to GD&T fundamentals covers the following with exercises throughout and a test for comprehension at the end. Sonora students will learn:

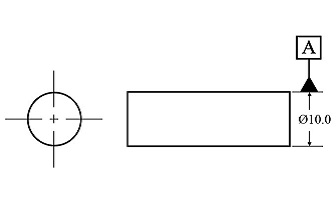

| | Overview. Units of measure, fundamental dimensioning rules, terms, material conditions, extreme form variation, allowance, clearance, and types of fit.

|

| | Symbols. Dimensioning symbols and templates, datum features and targets, geometric characters, material conditions, and feature control.

|

| | Datums. Symbol, surface, frame, and target. Also includes partial and coplanar.

|

| | Material Conditions. Limits of size, perfect form boundary, regardless of feature size (RFS), maximum material condition (MMC), least material condition (LMC), datum feature hierarchy, and datum precedence.

|

| | Form and Profile. Straightness, flatness, circularity, cylindricity, profile, and, free state variation.

|

| | Orientation and Runout. Orientation, runout, combinations, tangent plane.

|

| | Location. Position, coaxial features, non-parallel holes, slotted holes, spheres, fasteners, projected zones, virtual conditions, concentricity, coaxiality, and symmetry.

|