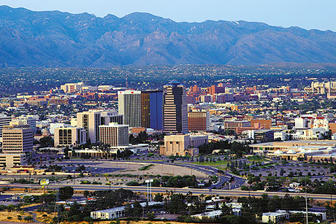

Cities Recommended in Arizona

All Cities

About Single Minute Exchange of Dies (SMED) / Quick Change-Over Training

Who is Single Minute Exchange of Dies (SMED) / Quick Change-Over Training for?

Single Minute Exchange of Dies might sound limited in its scope. However, while the technique was born in sheet metal stamping operations, its lessons have wider appeal. Generally, SMED deals with process changeovers to switch from manufacturing one part design to another. There was a time when massive dies used by automotive manufacturers required days to change. In this extreme example, large downtime cost necessitated improvement giving birth to faster, single-minute, and even one-touch exchange of dies. Since the lessons of faster process change-over can be applied to any process which switches over to run more than one part design, if you have a process like this, then SMED Training is for you. In our course, Arizona students learn:

Single Minute Exchange of Dies (SMED) / Quick Change-Over Training Course Overview:

The faster you can set up a new part to be machined, or change over to a completely different part can have big impact on operational efficiency. So, Arizona students learn how to study their existing change-over process and speed it up using the 8 traditional techniques:

| | Segregating external setups from internal.

|

| | Converting internal steps to external.

|

| | Using standardized function.

|

| | Giving preference to clamps over fasteners.

|

| | Using intermediate jigs.

|

| | Breaking sequential tasks into parallel tasks. SMED is essentially a project management tool in which Gantt Charts can be helpful.

|

| | Eliminating the need for adjustments each of which are essentially rework operations.

|

| | Evolve towards mechanization.

|